Food Safety Ventilation Systems Custom Engineered for Your Facility

FSMA Compliance & Operational Efficiency Experts Design of Ventilation Systems

Key Design Products

- Kitchen Ventilation

-Fans & Ventilators

-Ductwork

-Make-Up Air

-Heaters

-Dust Collection

-Core Ozone Units

Since the Clean Air Act of 1970, Green Earth's Engineers have been at the leading edge of industrial ventilation system technology and engineering. Our innovative designs have saved millions of dollars for a wide range of manufacturing and processing facilities. We incorporate regenerative oxidizers, energy recovery systems and even industrial dust collection systems for a completely turnkey system. Green Earth industrial ventilation engineers have over 40 years of experience designing and implementing custom solutions for food manufacturers throughout the industry.

Improper placement or poor design of an air filtration system can cause the system to run less efficiently, even leading to overall system failure. Depending on what is being processed in the plant, the level of air filtration needed can vary. Many factors play a part in putting a ventilation system in your food safety facility, like negative pressure. Negative pressure refers to if a door or window is opened in the building, the air pressure will suck air into the building. This allows unfiltered particles and pollutants to enter the building, compromising safety.

Food Safety Modernization Act Compliance

The Food Safety Modernization Act, signed into law in 2011, emphasizes the necessity of contamination prevention rather than response. Meeting FSMA compliance and maintaining the safest air quality is essential for every food processing and manufacturing facility. Green Earth’s food safety ventilation engineers are well versed in the nuances affecting air quality inside food production amenities.

Laws and requirements of the FSMA vary across different state and local levels. Depending on your facilities location, our food safety ventilation experts will create a custom system which will meet all the codes and regulations required. Even the placement of the food ventilations system has an effect on the requirements needed to adhere to laws and codes.

Incorrect calculations and designs lead to less efficient daily operations, while falling short of current regulations. These shortcomings will need to be fixed or your facility could face a hefty penalty. This accumulates into costly expenses, causing you to spend more time and money on something which could have been done right the first time by Green Earth, Inc.

Our engineers specialize in identifying potential airborne contaminant sources in food manufacturing facilities. This information is used in designing a turnkey industrial ventilation management system eliminating potential contaminationwhile also maximizing operating efficiency and saving money for our clients.

Food Safety Ventilation Clients

From pet food to coffee roasting, Green Earth's Engineers have saved millions of dollars for a wide range of companies in the food manufacturing and processing industry.

Whether you need a system designed for a new building or need your current one replaced, Green Earth Engineering has the knowledge and experience to complete any sized job quickly and efficiently. No matter what type of food processing is taking place in your building, our food safety ventilation experts will custom design a comprehensive system, which will run efficiently and effectively for the long haul.

Just a few of our food safety ventilation clients our engineers have worked with include:

|

|

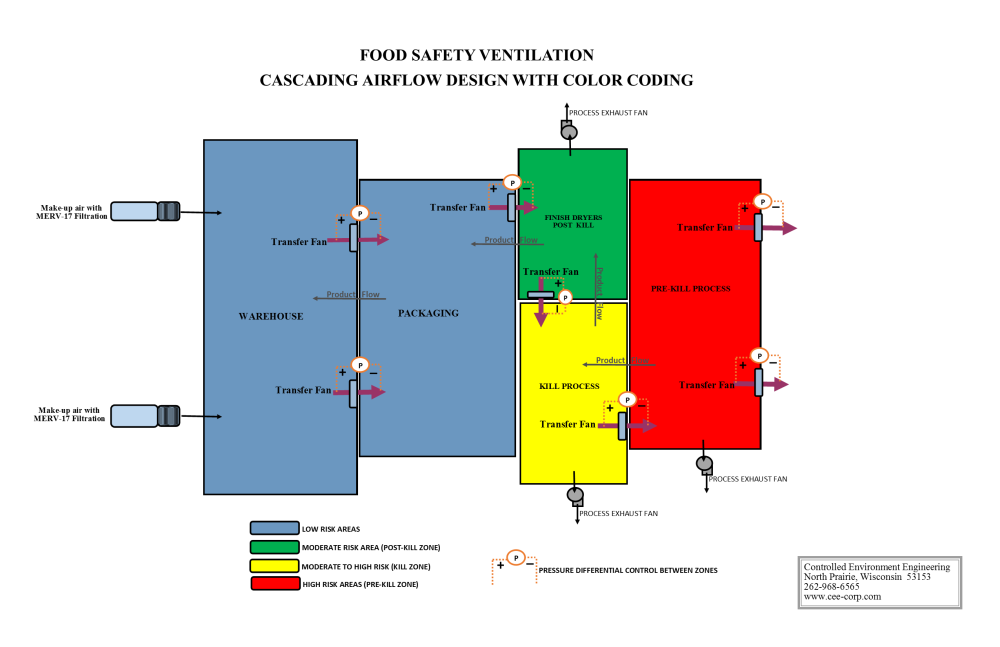

Example of Cascading Airflow Design Color Coded